The purpose of optical coatings is to change the reflectivity of optical surfaces. According to the materials and physical phenomena which are used one can in principle distinguish metallic and dielectric coatings. Metallic coatings are used for reflectors and neutral density filters. The reflectivity which can be achieved is given by the properties of the metal. Dielectric coatings use, however, optical interference to change the reflectivity of the coated surfaces. Another major difference is that the materials used for this kind of coatings show very low absorption. Using optical interference coatings the reflectivity of optical surfaces can be varied from nearly zero (anti reflection coatings) to nearly 100% (low loss mirrors with R > 99.999%). However, these reflectivity values are achieved only for a certain wavelength or wavelength range.

A dielectric mirror, also known as a Bragg mirror, is a type of mirror composed of multiple thin layers of dielectric material, typically deposited on a substrate of glass or some other optical material. By careful choice of the type and thickness of the dielectric layers, one can design an optical coating with specified reflectivity at different wavelengths of light. Dielectric mirrors are also used to produce ultra-high reflectivity mirrors: values of 99.999% or better over a narrow range of wavelengths can be produced using special techniques. Alternatively, they can be made to reflect a broad spectrum of light, such as the entire visible range or the spectrum of the Ti-sapphire laser.

| Material | Optical Glass |

| Diameter | as per your request |

| Diameter Tolerance | +0.1mm |

| Thickness Tolerance | +0.1mm |

| Parallism | 3 arc minutes |

| Edge Thickness | 3mm |

| Flatness | λ/4 |

| Surface Quality | 80/50 60/40 40-20 |

| Bevel | 0.25 mm*45° |

| Coating | dielectric coating |

Other Items

Factory information

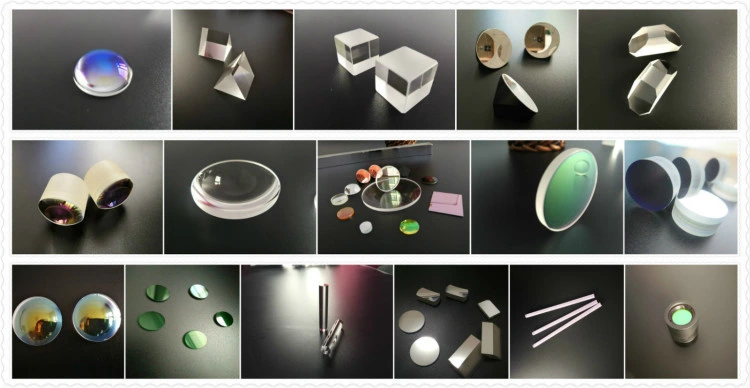

Yutai Optics, we specialize in the design and volume manufacturing of high performance optical components such as lens,prisms, windows,filters,mirrors and more for use in optical instruments and laser systems, as well as for military, telecommunications,medical, environment monitoring industry,material is widely ranged from optical glass to IR and UV glass.

As a Fast-growing supplier in Optics, Yutai Optics offers excellent service and good quality items,our products have been appreciated by many European and American customers,of course we build a long-term cooperation.YuTai Optics has quickly established itself as a leader in optical components from its advanced technology and quality control.

Our Advantage

Sells Team

Yutai Optics has a professinal sells team with excellent service, we tracking from inquiry to delivery of items.We try our best to meet each customers'request.

Produciton Team

Yutai Optics has many experienced engineers and advanced machines, they are the important guarantee for the higher quality products.Our advanced production machines list:

Ring polishing machine, Single axis machine, Two axis machine, Four axis machine,Centering edging machine,Mechanical milling machine,Spectrograph, Grinding machine,nanotech.250upl,talysurfi120.

Inspection Team

Advanced testing equipment and methods are important guarantee for the production of high-precision products.Our testing machine is ZYGO, Stereo interferometer,Horizontal interferometer.We provide testing report for each batch for your items.

Process for most optics

Material-cutting-rounding-milling-grinding-polishing-edging-cleaning-coating-gluing-edging-blacking-accembly-packing-shipping

Packaging & Shipping

1 Package Detail: A. Standard carbon and envelop with plastic foam.

B. Safety green carton.

C. Customized.

2 Delivery Detail: Within 30 days.(Also depand on the quantity)

Payment: